Timber-framed building structures: construction and technology

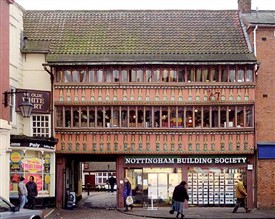

Old White Hart, Market Place

A. Nicholson

The Old White Hart Inn, rear

A. Nicholson

The Governors' House

A. Nicholson

A report on a practical exhibition and presentation by Mr. Michael Flinton, in Newark Library

By ROGER PEACOCK

10th September 2012

The Construction of Mediae val Timber-framed Buildings: a ‘Hands-on’ Demonstration by Michael Flinton in Newark Library

Mr. Michael Flinton, a local historian with an enthusiasm for mediæval joinery, exercised a practical presentation of the designs of timber-framed buildings, those landmarks in evidence in much of Newark town centre, notably in Kirk Gate and Stodman Street. Participants were shown the piecing together of the framework which provided, and provides, stability to the structures. Each section was shown independently, allowing the audience to handle beams and trusses, as well as the rounded wooden pegs that enabled secure erection. No metal was used in the structure. The technology of each joint could be both seen and handled that evening.

There was, said Mr. Flinton, no shortage of demand for efficient carpenters. Much of the land was forested; in terms of Forest Law, Sherwood Forest covered two-thirds of the acreage of Nottinghamshire. Restrictions on the felling of timber for house-building applied mainly to the rural peasantry; any environmental policy of deforestation or preservation of trees lay well in the future. Special laws of the forest forbade only the killing of the king's deer for venison. The Bishop of Lincoln was Lord of the Manor of Newark; Bishop Alexander, a previous holder of that post, had initiated the building of Newark Castle and hence the birth of the ‘real’ township. In accordance with the Domesday Book the Lord had stewardship of his patch. Forest land, then, would have afforded a large reserve of timber supply. It was certainly the readiest and most practicable local material for its purpose; brick was not yet mass-produced locally, and suitable stone was more difficult to obtain. Oak was most plentiful in this area; oak had both weight and, in the case of green oak, potential for carving joints or embellishments.

Typically, a mediæval house would have comprised a pantry and buttery at one end, a central hall beyond the screens passage, and the solar, or sleeping-quarter, at the other end. Structurally, the upper storey tended to be jettied, that is built to protrude more broadly than the ground floor, although the technological explanation of this strategy is open to question. The entire building would have been sixteen feet tall, which would have made it very heavy and stable, the floors and cross-beams needing to withstand some considerable downward thrust. Side-axes and saws were used to prepare the framework components, although the last-named was less commonplace in its application.

At the beginning of the presentation, the girding-frame was seen to be divided along the longer sections of its horizontal rectangle. There was no accurate mathematical calculation of measurements, few possessing then the ability to read. Mason's marks alone demarcated the division and erection of the timber lengths. Man had learned how to make mortice joints, and these enabled a basic cuboidal shape. The framework trusses probably were raised using a mechanism with trunion pivots like a gun-carriage to centre the foot tenons into the sill mortices without the heavy upright timbers sliding about. The sockets for the pivots were then plugged,ensuring that the framework fitted compactly and securely. Plugging, using pegs that would have been centred by machine, ensured that the framework fitted compactly and securely. Timber pegs were rounded by the use of a drawknife.

Mr. Flinton then proceeded to assess the strength of the skeletal framework as a unit. Much of the solidity relies upon the ability of the ground floor to support an upper storey and a roof without fear of potentially disastrous top-heaviness or uneven distribution of first-floor weight. With regard to the thickness of timbers, there was no problem; a typical beam cross-section might be twelve inches broad and deep. Moreover, one notes the way in which oak grows – an examination of the bole of the trunk would expose narrow rings. Oak grows just 1/32 of an inch annually, resulting in a close-set grain in the timber, giving a high degree of tensile strength and load-tolerance. Below the jettied first floor, securing the rigidity of the rectangular framework underneath, the latter would be fixed by means of either a horizonat cross-beam or a diagonal beam, termed a ‘dragon-beam’. Where the longer side of the downstairs floor was divided and jointed would be a horizontal beam spanning the shorter side of the cuboid, thus dividing the horizontal rectangle on which an upper floor of planks would rest. All horizontal beams would have been securely pinned in order to exclude any loose play and possible collapse of a mortice joint. Insomuch as the structure owned any weakness, it lay in the dubious wisdom that the ground floor only accounted for 1/3rd of the overall height, and that was without the gable ends and pitched roof! It does not take much imagination to realise that the upper storey must have weighed three or four times as much as the lower, and that its mathematical volume would have been more than twice as great,allowing for the jettying. Clearly, much depended upon the supportive strength of the lower structure; although it is true that the upstairs beams were thinner, which may have provided some compensation.

The speaker then went on to demonstrate the construction of the upper storey. The joists simply sat on the outer cross-beam, whilst being securely pinned to the inner. The next row of uprights was then attached by mortice-and-tenon joints. A different joint, called a ‘bird's mouth’ joint, which has three sections resembling the flight of an arrow in shape, fastened the long section of the upper end beams. The ‘knees’ of the building could then be ornamented for æsthetic effect. Wind-bracing in the form of short diagonal beams at the gable ends gave a final measure of stability to the two storeys, before attention was paid to the gables themselves, and to the roof design.

The gables were seated on top of the central rafter, and were supported by ornamented king-posts generally visible in the complete buildings. Gable technology was imaginative, yet simple, and effectively consisted of an inverted ‘V’ shape at each gable end, supported at the apex by a connective pearling beam. No further support was required at the base, the upper storey framework being sufficient. Smaller and slimmer rafters would provide a surface on which to build up a roof, and this would be done by means of thatching. Thatching provide a rainproof coverage which readily shed surface water thanks to its composition and its pitched design structure. With such a roof in place, the half-timbered house could enjoy a great life-span. It should be noticed that no modern technology, such as power supply, was or could be provided. The kitchen was built, where it existed at all, as a separate unit, and there was no such thing as sanitory provision. The gutter outside was the only facility for waste, including lavatory sewage, so disease was rife in the days when these buildings went up. Open fire would provide both heat and light, usually set in the centre of the hall and served by primitive chimneys or smoke-holes. There was not even a staircase to give access to the upper floor until the late 1400s; but rather an oak stair-turret that was located outside the house. Nevertheless, the homes provided all the comfort that mediæval folk asked for, or indeed knew of. Windows and doors would be included in the walls, the window mullions set digonally. The earliest windows simply had shutters to seal them from the elements, but diamond-shaped panes of glass set in lead became available during the Tudor years.

As to the infilling of the walls, it would generally be of wattle-and -daub, although there was some knowledge and use of plaster. Six carpenters would set about the task of building each house, using tools that were using tools that were hand-made by a blacksmith. Such tools, adzes, axes and chisels had hammered handles, and were treasured possessions that were personal to each carpenter. The carpenter was the original home-builder, preceding the stonemason. Oak continued to be the only material available for the purpose whilst forest reserves lasted. Rarely was an alternative to be found until sweet chestnut - which when green was more workable than oak - came into use in the 1600s. By this time oak had dwindled in availability, a decline which had begun during the fourteenth century. Chestnut was less likely to dull tools' edges as quickly. Meanwhile, though, there were plenty of coppiced estates available to provide timber, especially after the English Reformation and the deposition of monasteries by King Henry VIII.

It has, of course, been difficult to describe in words that which Mr. Flinton made such an excellent job of demonstrating practically. This report has been an attempt to do just that. A far better insight can be gleaned by looking for oneself at some of the half-timbered buildings that Newark owns, although it can sometimes be difficult to access the interiors if they are not open to the public. The Governors' House on Stodman Street is one that can be witnessed in all its splendour, as its conversion into a shop and restaurant means that it can be entered and the construction technology viewed. The longest-standing subject is the Old White Hart in the corner of the Market Place, now a branch of the Nottingham Building Society and a row of retail outlets, but in its heyday a coaching-inn. Yet there are others nearby. They have been a feature of this historic town for several centuries and, properly-maintained, will be standing for some time yet!

The subject has proved a fascinating insight into mediæval heritage, and the presentation by Mr. Flinton was an experience not to be missed.

© Roger Peacock for NALHS: 11 th September 2012

Edited by Michael Flinton 1 st October 2012

Acknowledgement: The presentation was part of the heritage weekend organised by the Newark Archæological and Local History Society with the help of other heritage groups.

Special thanks are due to Mr. Michael Flinton, the local and County Councils and to Local Studies Librarian Mr. Tim Warner.